6063 aluminum alloy has good casting properties and is suitable for die-casting processes. 6063 aluminum alloy is renowned for its excellent casting performance, low density, good mechanical properties, and excellent corrosion resistance. These characteristics make 6063 aluminum alloy very suitable for die-casting processes.

1. 6063NT is a heat treatable strengthening alloy with moderate strength in the AL Mg Si system, and is also the aluminum alloy with the best thermal conductivity after pure aluminum, with a thermal conductivity coefficient of up to 201w/m.k. At present, there have been significant breakthroughs in the application of optical communication modules, and superior brazing performance has been applied in the thermal management system of new energy vehicles.

2. After nano treatment, it can be die cast into shape. After T6 treatment, its yield strength is 225MPa, tensile strength is 255MPa, elongation is 9%, and HV hardness is 80

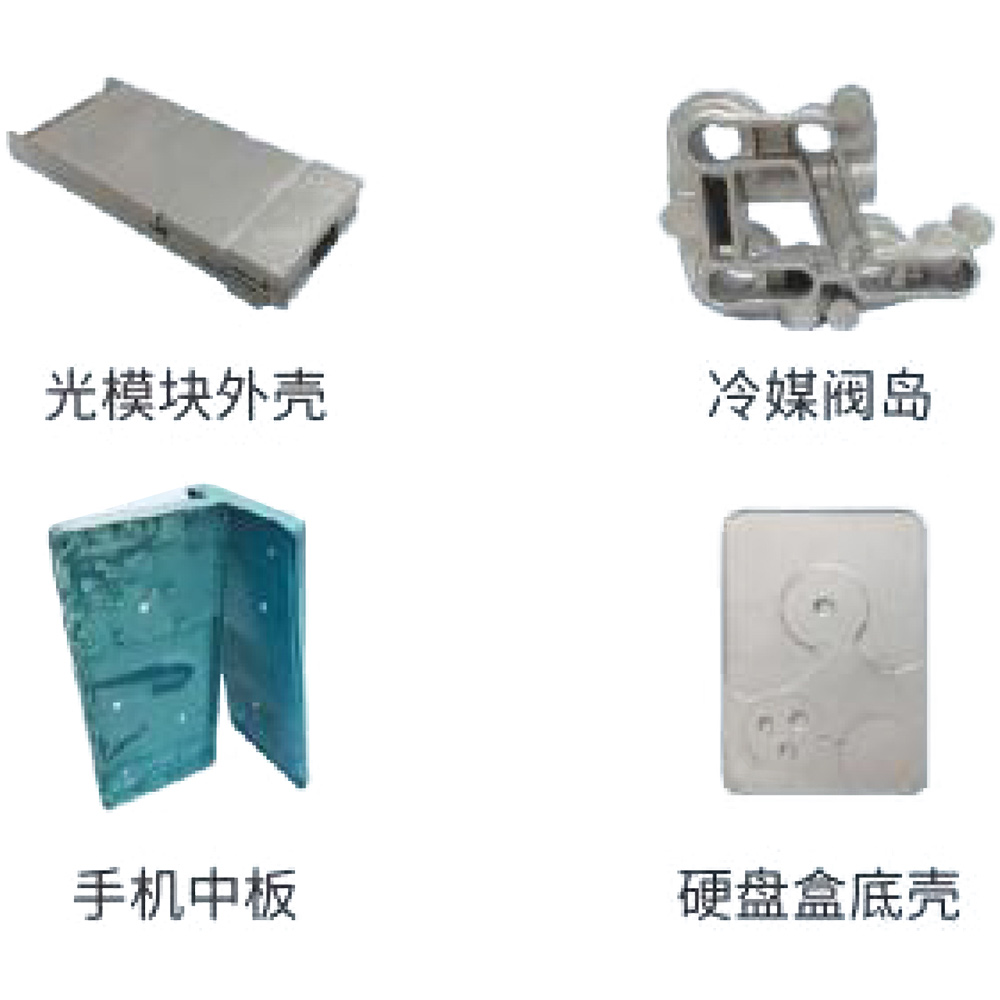

3. Widely used in components with high thermal conductivity requirements such as mobile phone motherboards, tablet shells, automotive refrigerant valve islands, optical modules, hard drives, etc

Specific manifestations of casting performance

Good fluidity: 6063 aluminum alloy has good fluidity in the molten state, which can smoothly fill the mold and form smooth castings.

Strong filling ability: During the die-casting process, 6063 aluminum alloy can effectively fill the mold, ensuring the accuracy and integrity of the casting.

Heat treatment strengthening effect: Heat treatment can further improve the strength and hardness of 6063 aluminum alloy, meeting different application requirements.

Factors affecting casting performance

Casting temperature control: In practical operation, it is necessary to strictly control the casting temperature to ensure the fluidity and filling ability of the alloy.

Mold design: The design and manufacturing quality of molds have a significant impact on the quality of castings, and it is necessary to ensure the accuracy and durability of the molds.

Alloy composition: The composition of an alloy can also affect its casting performance, and appropriate composition adjustments can optimize the casting effect.

|

Nanotechnology based deformable aluminum alloy for die-casting Alloys NT |

Mechanical performance Mechanical Properties |

thermal conductivity Thermal Conductivity Coefficient (W/mK) |

||||

|---|---|---|---|---|---|---|

|

Brand number Alloy brand |

Performance status Status |

yield strength YS(MPa) |

tensile strength UTS(MPa) |

Elongation rate Elongation(%) |

hardness Hardness(HV) |

|

| 6063NT | Die cast state | 91 | 157/ | 20-25 | 50 | 190 |

| T5 | 130 | 190 | 15 | 65 | 179 | |

| T6 | 225 | 255 | 9 | 80 | 192 | |

Email: mail@metali.com.cn

Enterprise Address: Building B, Shunxingwang Factory, No. 50 Xinqiang Road, Liuhe Community, Pingshan Street, Pingshan District, Shenzhen, China